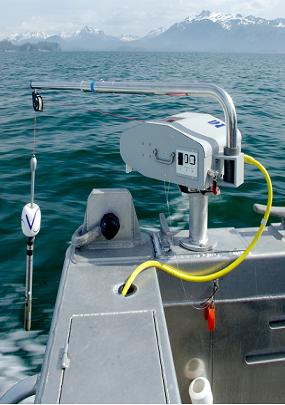

The facility used to depend on outdated hard wiring and touch-tone telemetry to coordinate and control the water flow. The old system had to control pumps, gates, and valves as the water came from six wells, through the aerators, and finally to the fish raceways. As it became harder to repair the old equipment, and as new technology matured, Pequest's managers contacted Campbell Scientific because of our worldwide experience in aquaculture instrumentation.The new instrumentation made several major improvements in the monitoring and control system. One problem that needed to be addressed was the distance between the wells, pumps, and control center. Our engineers implemented spread-spectrum radio technology to connect all of the hatchery system components and avoid the problems and maintenance costs of land lines.Dataloggers connected to the radios at each location monitor and control pumps, flow meters, alarms, and an integrated meteorological station. Duplicate home bases were set up at two locations for backup and for wider access to data and control features. When alarms are activated, the new system can sound sirens, automatically make phone calls to staff members, and even shut down equipment if conditions require it.One benefit of the new system is that its low power use and backup batteries ensure uninterrupted data collection, even during power outages. Another benefit is that the system is expandable, allowing new wells to be added and new monitoring and control components to be brought on line.Pequest Trout Hatchery has become, with some help from Campbell Scientific, one of the most modern and efficient hatcheries in America.